Corrado I, Petrillo C, Isticato R, Casillo A, Corsaro MM, Sannia G, Pezzella C*

Int J Biol Macromol. 2021 Oct 31;189:494-502. doi: 10.1016/j.ijbiomac.2021.08.123.

Abstract

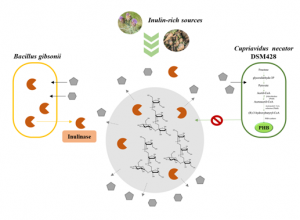

One of the major issues for the microbial production of polyhydroxyalkanoates (PHA) is to secure renewable, non-food biomass feedstocks to feed the fermentation process. Inulin, a polydisperse fructan that accumulates as reserve polysaccharide in the roots of several low-requirement crops, has the potential to face this challenge.

In this work, a “substrate facilitator” microbial consortium was designed to address PHA production using inulin as feedstock. A microbial collection of Bacillus species was screened for efficient inulinase producer and the genome of the selected strain, RHF15, identified as Bacillus gibsonii, was analysed unravelling its wide catabolic potential. RHF15 was co-cultured with Cupriavidus necator, an established PHA producer, lacking the ability to metabolize inulin. A Central Composite Rotary Design (CCRD) was applied to optimise PHA synthesis from inulin by the designed artificial microbial consortium, assessing the impact of species inoculum ratio and inulin and N-source concentrations. In the optimized conditions, a maximum of 1.9 g L-1 of Polyhydroxybutyrate (PHB), corresponding to ~80% (gpolymer/gCDW) polymer content was achieved. The investigated approach represents an effective process optimization method, potentially applicable to the production of PHA from other complex C-sources.